Pumori-Energy

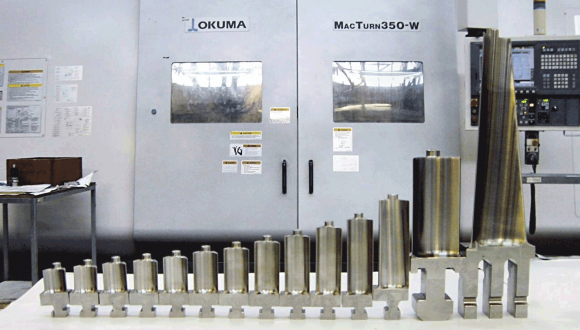

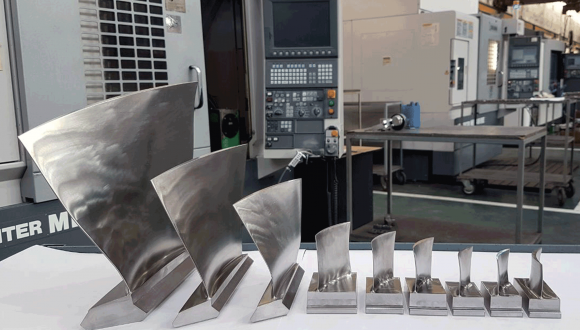

Pumori-Energy Ltd is a Russian specialized company producing blades and vanes for steam and gas turbines, as well as for compressors.

The company was established in 2001 and is a member of Pumori Corporation.

During these years, Pumori-Energy has travelled a long way of development, has proved itself as a reliable and responsible partner. The company has regular customers; its products are well known in Russia and also exported to other countries.

Pumori-Energy has developed and implemented a new technology for blade and vane machining, which was used in the production system — revolutionary for the country’s industry — to make blades up to 1000 mm high.

THIS TECHNOLOGY PROVIDES:

- Creation of a 3D computer model of a blade/vane;

- Development of control programs for machining centres;

- Creation of single bases for blade/vane machining;

- Minimum tooling for machining and measuring;

- High-speed milling in modern 4 and 5 axis machining centres;

- Use of carbide cutting tools by leading foreign manufacturers;

- Dimensionless polishing of the working part of blades/vanes;

- Accuracy check in a coordinate measuring machine;

- High precision of manufacture of all elements of blades/vanes.

The company uses licenced automated programming systems for turbine blade/vane milling, the core of which is software from AutoDesk and Siemens PLM Software.

Pumori-Energy has a control system consisting of partial measuring of rough and finished dimensions of blades directly in machining centres and of measuring all necessary dimensions on coordinate measuring machines with PS-DMIS software outside the machining centres.

This system enables:

— Checking without traditional checking fixtures;

— High accuracy of measurement — 3.5–5.5 μm;

— Metrological comparison of nominal and measured 2D sections of a blade/vane;

— Examination of deviations from the blade profile visually on a computer screen;

— Print graphical representation of profiles and the deviation table.

Pumori-Energy has recently launched manufacture of blading for steam turbines of 6 to 1000 MW and gas turbines of 3 to 25 MW. Also, it has implemented manufacture of blading for turbine plants used in chemical and metallurgical factories. The company now makes blades and vanes from nickel alloys, BT 6, BT 8 titanium, and duralumin.

In 2009–19, Pumori-Energy manufactured and delivered over 310 000 blades and vanes (over 210 000. for steam and over 100 000 for gas turbines). Over 12 000 units were exported (to Italy, Greece, Cuba, China, Kazakhstan, Belarus, etc.).

For many years the company has been completing orders of Russian turbine makers (The Ural Turbine Works, Power Machines, Dalenergomash), generating companies (Mosenergo, PJSC Enel, Unipro, Eurosibenergo a. o.), service companies (Uralturbo, Lenturboremont, Servis-Sklad, Entechmach a. o.). Pumori-Energy cooperates with chemical companies, such as EuroChem, Uralchem, Acron, PhosAgro and their production divisions.

In the 1st quarter of 2020, Pumori-Energy successfully passed a surveillance audit of its Quality Management System for compliance with the requirements of ISO 9001:2015 carried out by Bureau Veritas. The scope of the Quality Management System covers production and sale of blades and vanes for steam and gas turbines.

Thanks to the action taken and implementation of the QMS recommendations the company has improved the quality and competitiveness of its products.

Also, Pumori-Energy passed a technical audit according to General Electric and Siemens standards in 2018–19.

PUMORI-ENERGY STRENGTHS:

- Highly skilled specialists;

- High quality of manufacture of blades and vanes due to using modern metalworking and measuring equipment;

- Rapid preproduction, ability to quickly manufacture pilot or new types of blades and vanes;

- Minimum production and measuring tools;

- Use of modern devices to check the quality of metals;

- Shortest production times;

- Competitive prices;

- Re-engineering competences (production of blades/vanes without a drawing by generating a 3D model to the specimen provided by the customer);

- Good reputation of the company.